The Process of Creating the Apple 1 Mimeo

How Did I Do This Project?

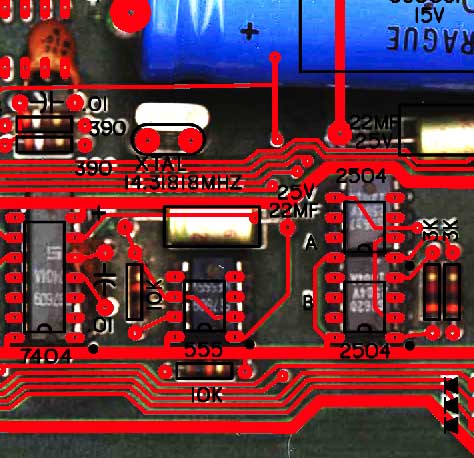

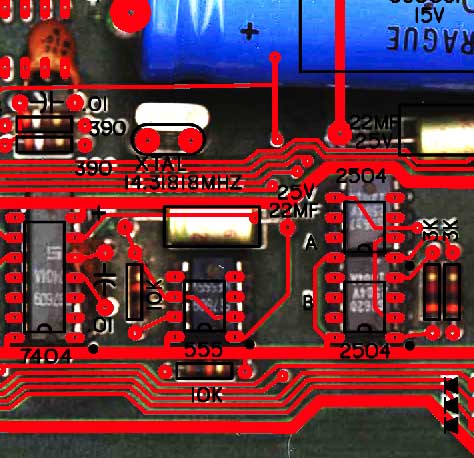

This

image will give you an idea of how I use the scan of an

original to make sure that component placement and traces are as

close

to the original as possible. The red overlay shows pad and

trace

placement as exported from my CAD program. The black is the

silk

screen layer, also exported from my CAD program.

Any discrepancies can easily be

seen

when this CAD output is placed in photoshop over the photo of an

actual

Apple 1 board. I expect most of the layout of the finished board

matches the original

placement within 10 mills. That is 1/100 of an

inch. There are some traces

that are routed under chips that are best guesses based on

experience.

Here is pre-production image

showing the PCB as seen in the CAD program. The final

production board has been tweaked and improved beyond what is

shown here.

- Black

is

silk screen

- Green is the front solder mask

- Red

is front copper layer

Check

out my blog for a

history of this project and continuing updates.

Check

out this

image of a pre-production version of the layout overlaid

over an actual

image of an Apple 1 (large file >1MB)

Note

that there is some distortion in the Apple 1 image, that may cause

less

than perfect alignment in some areas. This is particularly

evident in the upper left corner. The final production board

has been tweaked and improved beyond what is shown here.

- White

is

silk screen

- Red

is front copper layer

- Blue is solder mask over

fiberglass

- Purple is solder mask over copper layer

Follow this

link for some

info on parts and sources for the Apple 1

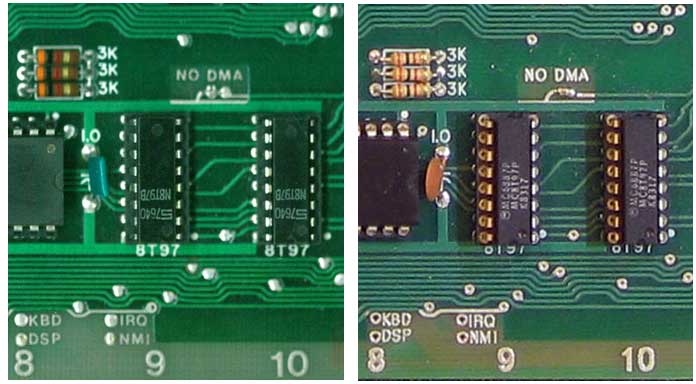

Results

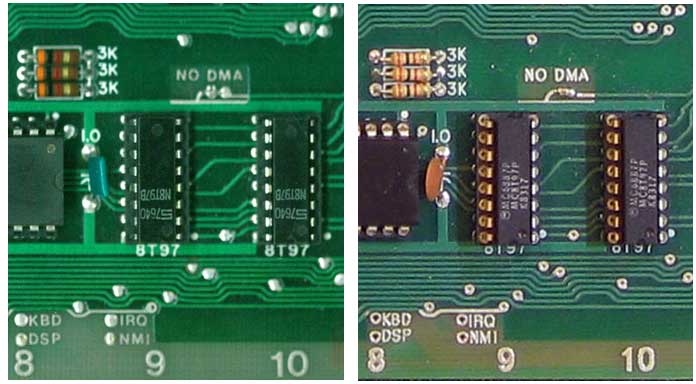

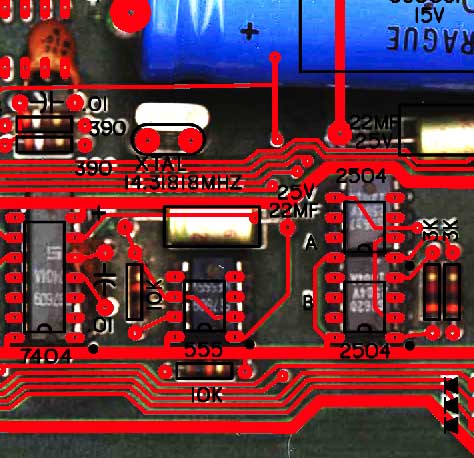

In

order to give you an example of the results, here are two larger

than life size

images - the image on the left is that of an original Apple1, the

image on

the right is a Mimeo 1.

One

of the things I'm most proud of, is the attention to detail I put

into

the solder mask layer. Note how the mask exposes some of the

trace above "IRQ", but not above "KBD". However there is just

a

nick cut out of the trace to the left of "KBD". Just a

sliver of the trace below "NO DMA" is also exposed.

I had to give the PCB manufacturer special instructions not to

"fix" these areas.

I

am also very satisfied how the lettering came out.

Recreating

the font and placing the letters was very time consuming. In

many

cases, I had

to individually place letters in order to get spacing between them

to

look the same as the original. The lettering that was etched

in

copper looks a

little heavy in these magnified web images. However they

look

fine when viewing an actual PCB. I have frozen the artwork,

and

I'm not likely to change anything in future production

runs.. In

my

experience, any improvement in one area can be offset by an

unintended

regression in an other.

Kit

Builder Feedback

I

received this feedback from the owner of an original Apple 1 and an

Obtronix Apple 1 clone. He bought a Mimeo kit as a learning

tool

for his teenage son, who was interested in computers.

- "I

have checked your Apple 1 board. It looks perfect. You did

excellent

job reproducing the original design. I am really looking forward

for my

son putting it all together."

Here more feedback from a person that at one time had several

original Apple 1s in his possession.

- "Wow! The board looks incredible. What an

impressive piece of work you've done. And the PC fab

facility as well."

more feedback from other folks

- "The kit arrived the other day, thank you! I had a quick

look at the board and it is beautiful!" - RL

- "Just

wanted let you know I got your kit! I have only opened it so far

and

looked at the manual and components. I am impressed with the

workmanship. Nice job! -RD

- "Everything is fine and it

worked on the first run without any problems." ... "Thank you

very much

for you perfect work! The board is really beautiful and some

older

parts as well." - ML

A few Mimeo owner's web pages and blog entries