If you haven’t been following my blog, you should go back to the first post of this series, in order to get caught up. At this point, I have found the cause of the missing horizontal sweep and the scope was working as well as it did prior to the coffee spill. I still had the two pre-existing issues and since I was gaining familiarity with the scope, I decided to pursue those issues.

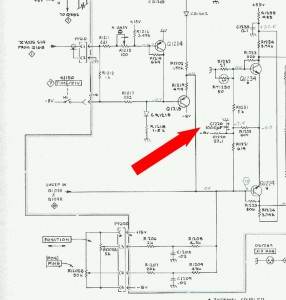

First thing to attack was the horizontal position control. This was fixed using essentially the same repair process as the trigger “A” control. There were a few differences. The horizontal position control is made up two potentiometers, instead of a potentiometer and a switch. The coarse potentiometer is 0-5K ohm pot and the fine is 0-50K ohm pot. This circuit can be seen in the lower left corner of the schematic showing the 1000 uF cap that was discussed in a previous post.

Testing with my DMM showed issues with both of them. Disassembly was easy, as the unit is held together with small machine screws and nuts. To ensure correct re-assembly, I took a couple of digital photos before taking it apart.

Once, disassembled, I flushed both pots with isopropyl alcohol a few times and worked the wiper back and forth. Testing with a DMM indicated that the correct behavior was restored with this simple cleaning. Re-installation was uneventful and testing showed that these position controls worked like they were supposed to.

Now I was really making progress. Ever since I first purchased the scope, these controls have never worked quite right.

The trigger “B” slope switch still wasn’t working – maybe I could also fix that. If I succeeded, I’d have every function working as designed for the first time since I’ve owned this tool.

to be continued…