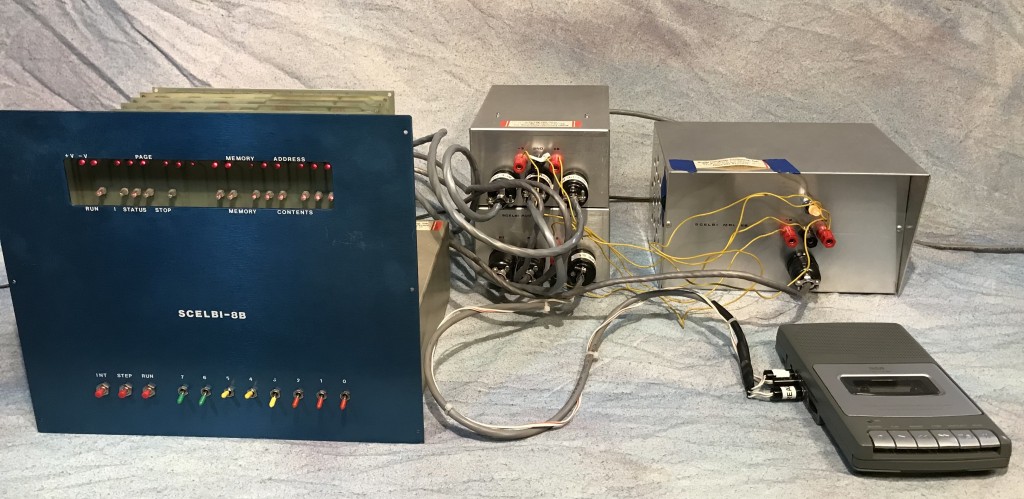

Back in 2015, I partially described how I used an early Apple serial card in an Apple ][ to provide a “glass” TTY emulation in order to check out some of my SCELBI software and interfaces. Since I don’t have a real TTY, I always had to set up the Apple ][ and download an emulation program via cassette tape interface in order to test the SCELBI with an TTY interface. Over the years, this has been an annoying bit of hassle, mainly because I usually forgot exactly what version of the software that I needed to download, exactly where in memory to download it, and what slot to put the serial card into.

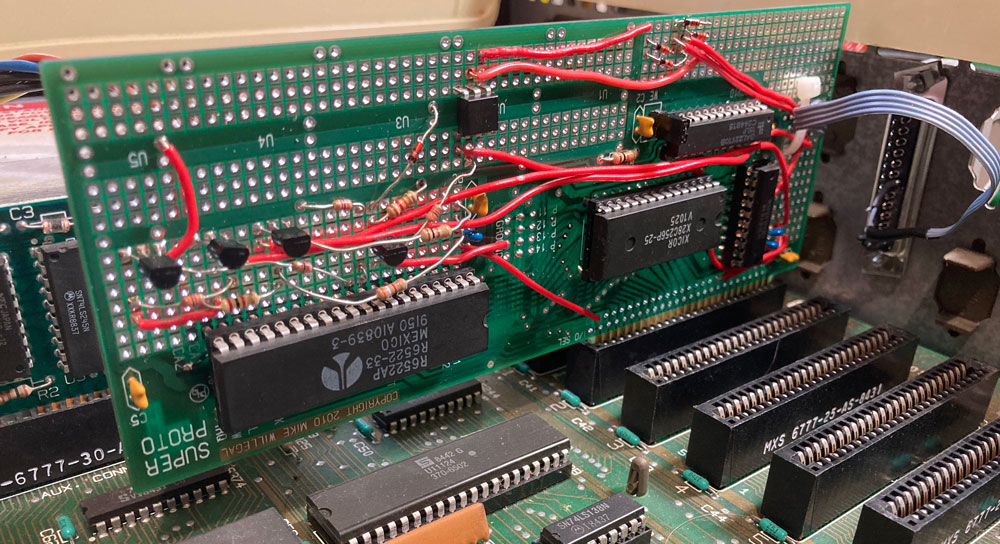

I knew that I could create a turnkey power on and go solution by designing and building a custom Apple ][ peripheral board. I just needed to copy the current loop interface from the Apple Serial card to a Superproto board and drive it with the Superproto’s 6522 VIA interface hardware. I knew I could easily port the program I had already written to run right out of the Superproto’s EERPOM. I first thought about doing this years ago.

Finally I started to do something at the beginning of this year, when I ordered the few required hardware components that I didn’t have in my stash. These parts came in right away, but, until now, I haven’t found the time to build up the board and port the software.

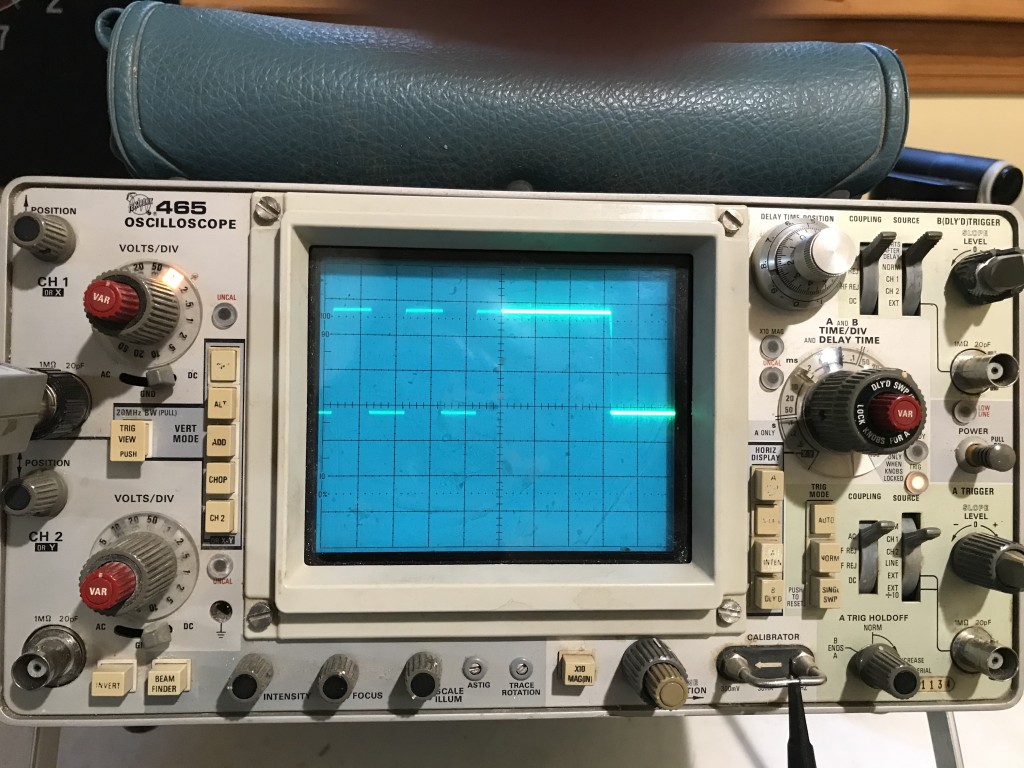

Well, I finally found the time to get this project working. I think the result is pretty cool. To connect a TTY with a 110 baud current loop interface to my SCELBI, I just connect the Apple ][e to a monitor, the SCELBI and power it up. No need to bother with floppy disks or cassette interfaces, or anything else. Since this card looks like a Disk ][ to the Apple, the Apple will automatically boot the TTY application, which resides in the Superproto’s EEprom.

I could potentially add logging, paper tape emulation and scroll back capability to this application, but I probably will not proceed with those ideas, at least anytime soon.

One other thing I might do, is create a version of software that will work at 45.45 baud and the Baudot charactor code, so I can use it with RTTY applications. I have done a simple version of this software for the Apple serial card, so it shouldn’t be too hard to port over. Since the Superproto supports multiple banks of memory in the EEPROM, I can use the same board and just put the RTTY app in a separate bank, and use the bank select jumpers to switch between TTY and RTTY applications.

Someday, I might make a custom card for this design, but I’m not going to do this unless I hear about some kind of demand for such a card.

Let me know if you are interested in seeing more details of the software and hardware design.