Remotoring the Mantua General

Part 2 - draw bar and drive shaft

Drawbar

A shorter, more prototypical draw-bar can be easily cut out from a

piece of PCB stock. First mark and drill the two 9/64" holes

.5" apart. Then using various cutting tools, you can cut the

outside dogbone shape using the original drawbar as a template. I

use a small band saw, dremel cut-off disks and various files to shape

the draw-bar. Make sure that the PCB copper layer is cut so that

there will be no connectivity between the locomotive and the tender

through the draw bar.

Drive Shaft Replacement

Materials required

- Guitar string .016" diameter (known as 016 music wire)

- 3/16" brass rod

- Hobbytown 100000K Universal Coupling Kit for 3/32" shaft

- ball

- socket for 3/32" shaft

- square drive rod

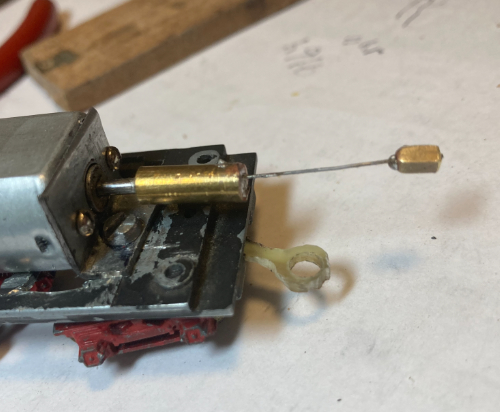

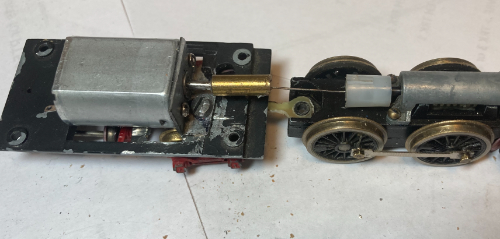

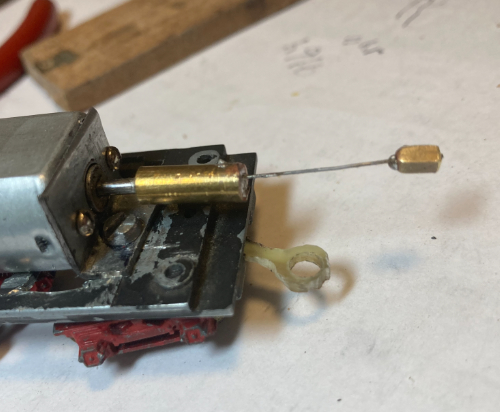

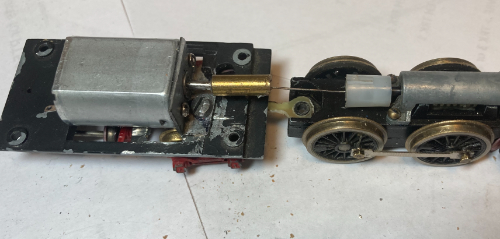

The Hobbytown 3/32" universal joint will fit perfectly onto the

Mantua/Tyco locomotive drive shaft. The square drive rod is cut

short and a small hole drilled to accept the music wire which is

soldered in place. It is a bit tricky to get a perfectly centered

hole, but if the hole is slightly oversize, the wire can be centered as it is soldered in place.

Adjust the length of the wire so it reaches from the drive shaft to just

short of the motor when the locomotive is coupled to the tender.

The motor end of the drive wire is soldered into a slightly oversized

hole drilled into the the center of a piece of 3/16" rod. I used a

#73 drill bit to drill this hole which is .024", .08" larger than the

music wire that I am using. The other end of the rod is drilled

with a 2mm hole to fit the drive shaft of the motor. After

soldering the wire into the rod, the rod is superglued onto the 2mm

shaft of the motor.

The hard part is now done. On the next page, I'll show how the DCC decoder is wired.

Back to Mike's

Hobby Home Page