Model Turntable Construction

This page is intended to at least partially document how I scratch

built a model of the City Point turntable for my City Point Terminal

model railroad.

Research

The first step was to gather all the images that I could find of

this turntable and similar ones built by the USMRR. I have

found two real useful images of the turntable at City Point.

I believe high resolution versions of all of these images can be

downloaded at no cost from the Library of Congress.

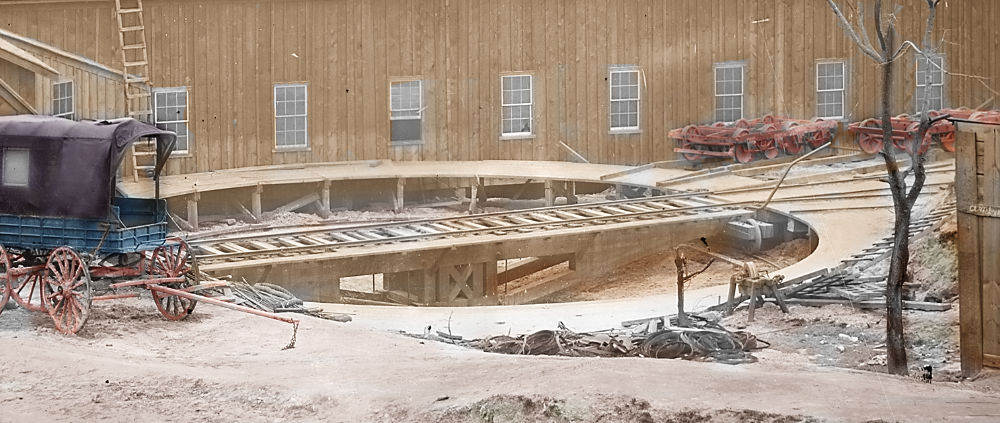

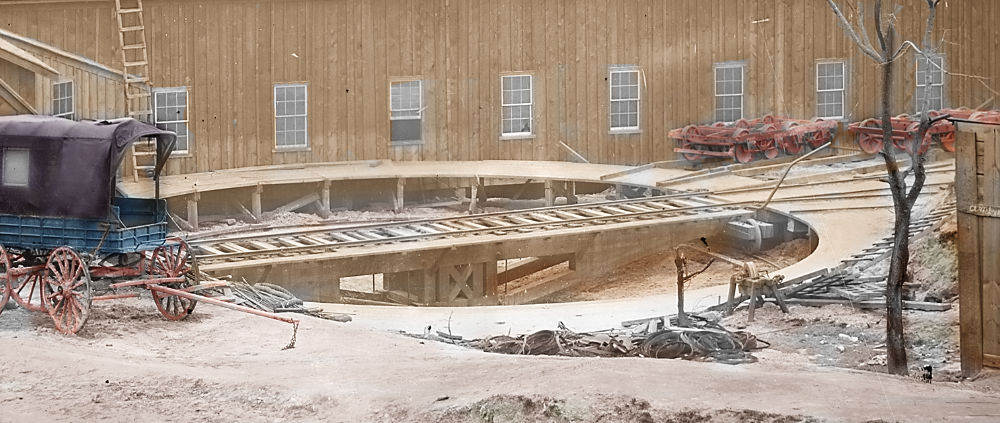

I had created a colorized version of this image a number of years

ago.

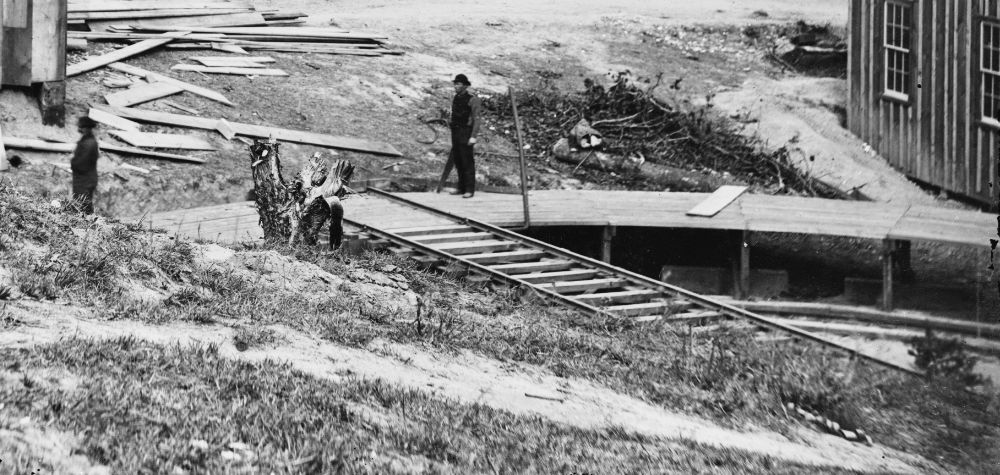

There are several additional images with some

aspect of the turntable in the scene, but they are of marginal

usefulness to the modeler.

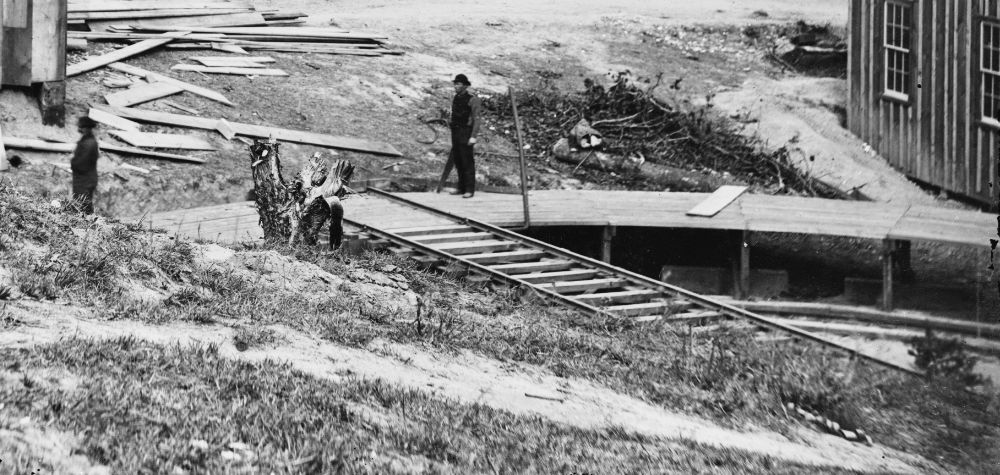

Here is an example where the turntable shows up in the image, but

not much in the way of details can be seen.

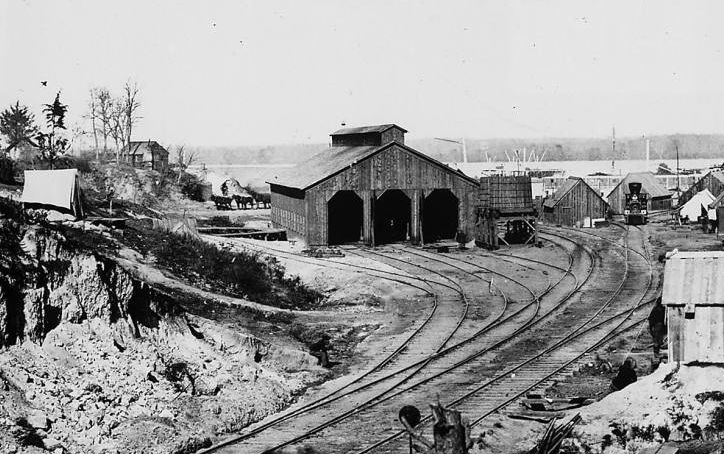

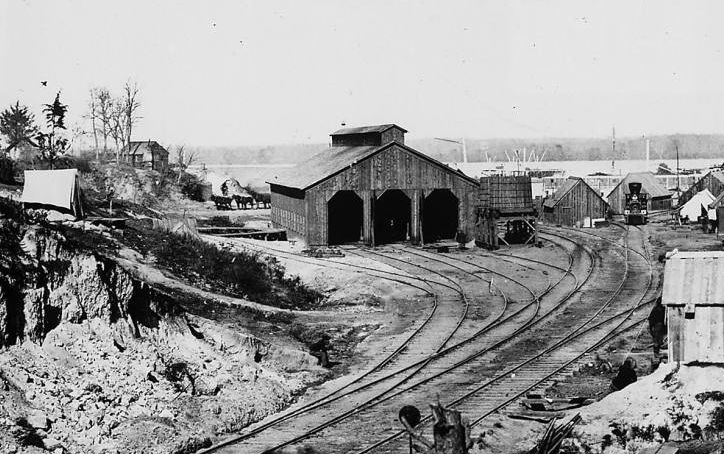

Bernard Kempinski found an image with a very similar turntable and

documented it on

his blog. You can search his blog for the keyword

"turntable" and find a number of useful articles. This

turntable differs in a couple of ways from the one at City Point,

but otherwise provides good detail. Two obvious differences

is that this one does not have a walk along the track and the

sides of the pit are framed.

The next step for me was to decide how to

approach constructing a model.

Mechanical Construction

Even though the historical City Point railroad

was manually operated, the idea of motorizing this turntable was a

no brainer for me. A number of years back I had built a

stepper motor controller for a barn

door sky tracker. This was supposed to be used to take

long exposure pictures of the night sky. I only used the

barn door tracker once. Years ago, I disassembled it

to use the motor to turn a rotating display that I used in a

vintage computer exhibit. I thought that operating a model

railroad would be a much better application for this motor.

The rotating display used a automobile wheel hub that I had

purchased off of eBay as the base and I figured that I could reuse

the hub as the pivot point for the turntable.

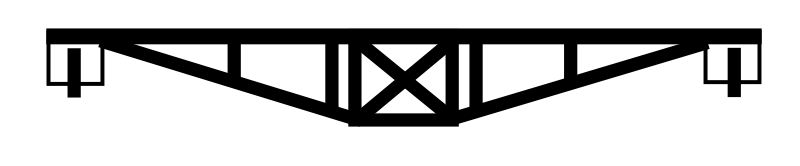

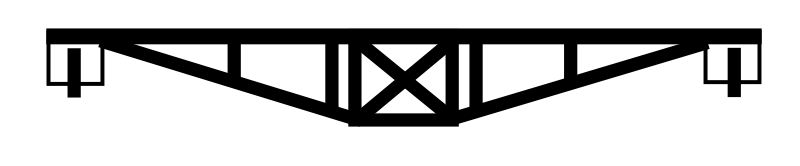

I decided to start with building the movable

bridge first and made an elevation view with an illustration

program. I did this in 1/87 scale so that I could print it

out and build the side frames directly on the drawing.

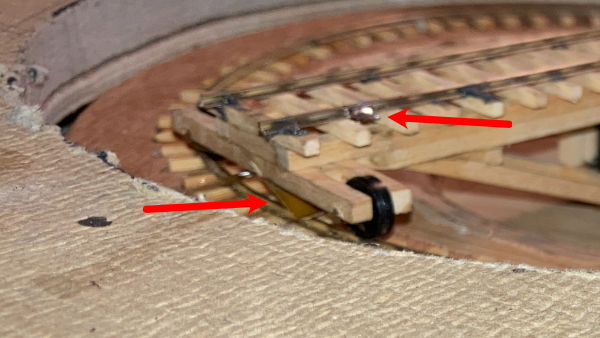

Before making the bridge itself, I made the trucks for the

wheels. I made these before the bridge side frames because the

ends of the stringers/joists meet up with these trucks in a very

specific wa. It would be easier to get rest of the model

right, if I already had the trucks built. I made the wheels

from from a couple of freight car wheel sets that were cut in

half. The trucks have semi-circular groves cut in the bottom

to hold the axles. The wheels are affixed to the frames with

brass strips attached at the center of the bottom. The flange

on each wheel was also ground off in order to give me a little more

room for error in putting down the rail. The wheels are easy

to slide off the ends of the frames, so I can upgrade them to the

spoked type seen in the pictures at a later time.

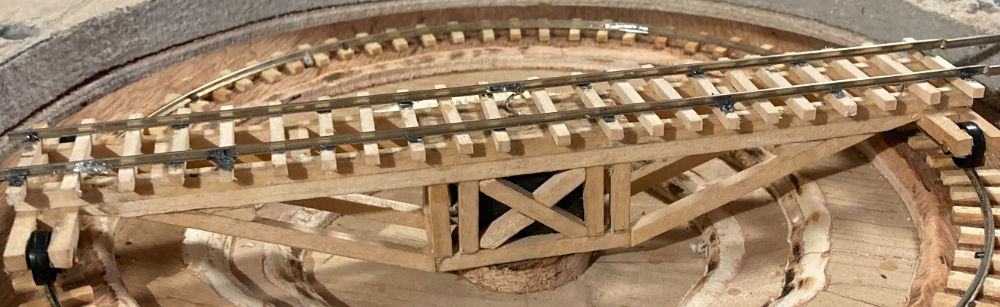

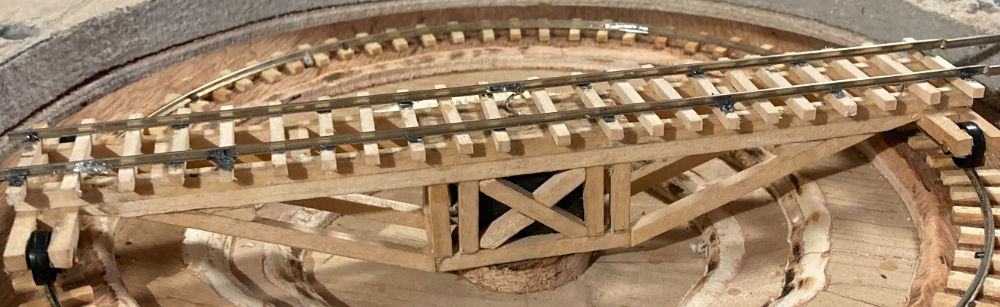

Next, I built the side frames for the

bridge. As I was cutting and gluing together the scale

lumber for the side frames, I noticed the joist/stringer at

the top was supposed to be doubled. I had to undo some of my

work to get this part of the model correct. The Northeastern

Scale Lumber was cut with a Micro-Mart chopper and glued together

with Titebond wood glue. Many pieces were trimmed to final

size with a Dremel type tool with a cut off disc installed.

After the two side frames were built, I joined them together with

additional pieces of lumber, making sure the spacing exactly

matched HO scale track spacing. I noticed long ago that the

stringers/joists on wooden railroad bridgework is designed to

support the rails in as direct a way as possible.

After joining the two sides, I noticed that the bridge was twisted

slightly. If not fixed, this would be a big problem as the

tracks on both ends had to be level or they wouldn't line up with

the lead in tracks when the turntable was rotated. I had not

yet installed the ties or track, so the remedy was easier than it

otherwise would have been. I loosened a couple of the key

joints and soaked the whole bridge with water and reglued the

loosened joints with the bridge clamped upside down on a level

surface. It still wasn't perfect after this effort, but I

figured that if it wasn't good enough, I could have another go at

it, later on.

By now, I had discovered in my stash, some 3/16" OD brass rod and a

matching 7/32" OD brass tube. It turns out that this brass rod

fits perfectly in the tube with almost no slop. I could use the

brass rod as the drive shaft for the bridge and the tube as the

bearing. This worked very well and I never did make use of the

automobile hub. Anybody want a very lightly used GM wheel hub?

At this point I decided to put a block of hardwood in the center of

the bridge to act as the support for the rod that I was going to use

to turn the bridge. I cut the block to size and painted it

black to minimize it's visibility before gluing it into place.

Now, I had to execute one of the most exacting operations of this

entire project. I needed to find the exact center of the

bridge (the center between all four wheels) and drill a 3/16" hole

for the drive rod that was exactly 90 degrees to the span of the

bridge. I did this, inserted the brass rod and found it seemed

reasonably close to ideal. I would find out more only after I

completed the pit. I drilled a hole into the side of the block

through to the center drive rod hole. This would to allow me

to add a wood screw that could be used to lock the drive rod and

prevent it from slipping.

Note that this bridge is surprisingly solid for such a small

model. I think the engineers that designed this structure back

in the day knew what they were doing. I put the bridge aside

and started work on the pit.

The pit is constructed on top of a square piece of 1/4" plywood

which acts as the base for everything, including the drive wheel and

stepper motor. I was afraid that the 1/4" thickness would not

be sufficiently stiff, but I think it will be fine, as most of

the base is reinforced by the 3 more layers that make up the pit.

The pit is made of 3 circles of 1/4" plywood, all with the same

outside diameter. A hole is cut in the center of each, with

smaller sized holes as you go down into the pit. Inner

dimensions are not critical, as this area will be modeled as dirt

and sand when I get to adding the scenic details. The

outside circles were cut on a band saw with a simple circle cutting

jig. The inside circles were cut freehand, following a line

drawn with a compass. The top inside edge of each circle was

rounded off with a router, which should help make the dirt/sand

effect a bit easier to model. Outside dimensions were chosen

to provide room for the guide rail and the walking platform that I

haven't yet modeled. The center point of the pit received a

small disc of 1/4" plywood. I figured that this would be used

to hold the drive rod bearing and would be mostly covered by model

sand and dirt when that was added.

The center point received a 7/16" hole in order to hold a piece of

the bearing tube. I tried to make this as close to 90 degrees

as possible as any deviance would cause the bridge to oscillate as

it rotated. Having a drill press helped with this alignment.

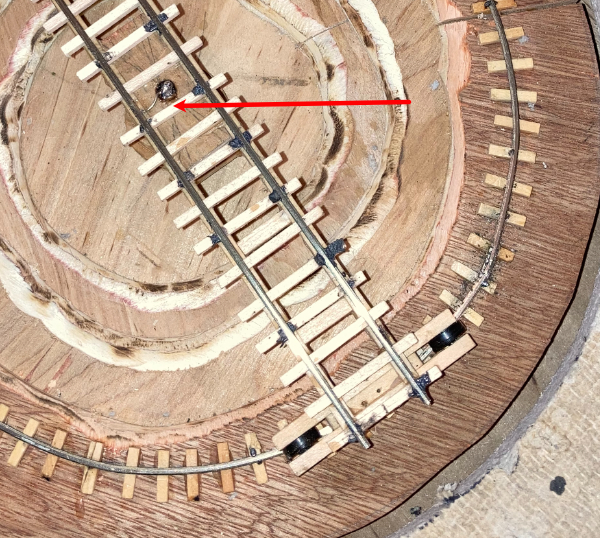

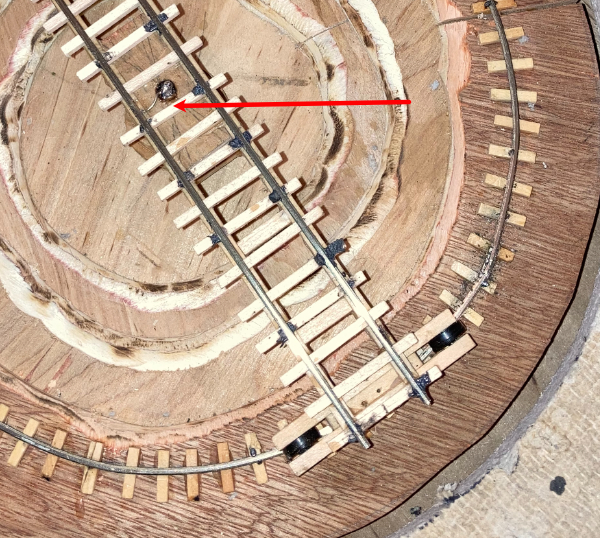

Once the pit was glued up, I used the center hole and a compass to

make a line to match the exact distance from the center point of the

bridge to the wheels. Note that this isn't the same as the

distance to the end of the bridge. Geometry comes into play

here and makes the wheels a slightly different distance from the

center than the end of the bridge. I glued down some shortened

ties centered on this line.

Finally, I bent a piece of rail into a circle as best I could.

I spiked the rail down, using the bridge with it's drive rod

inserted into the bearing as a guide. It took a lot of

tweaking to get the wheels to follow the rail correctly. I

eventually had to shim in a very small piece of extra rail in order

to make the diameter of the circle a hair larger than I originally

had it. Circumference = 2 x radius x PI works only if you

measure radius correctly.

At this point, I could check the level of the bridge as it

rotated. It turns out that it was off a little bit. I

decided to ream out the hole for the drive rod in the bridge just a

bit and then using the slop that was now available, glue the drive

rod into correct alignment.

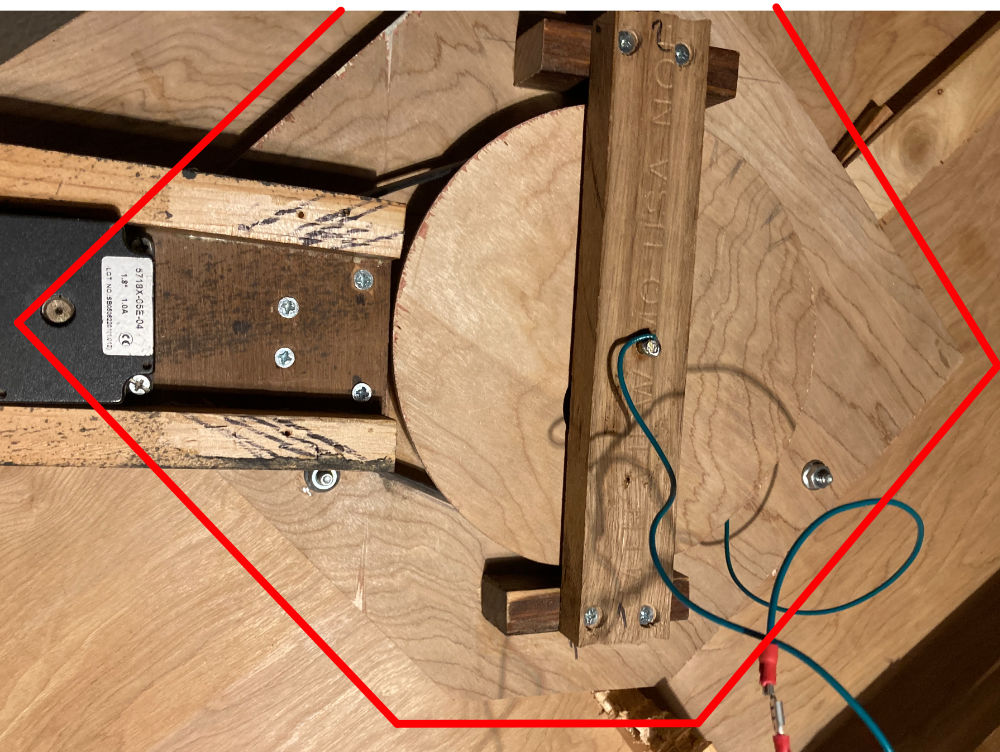

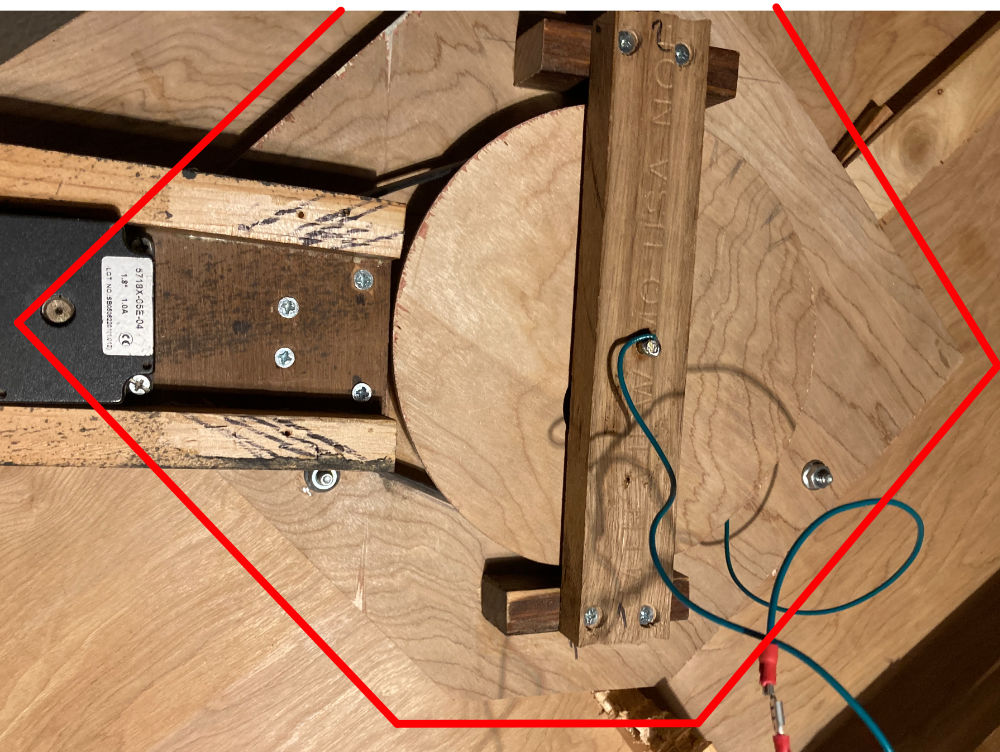

Next I had to fabricate a drive wheel and drive band so the stepper

motor could actually move the bridge.

The drive wheel is made up of two circles of wood. A 3/4" piece of

pine, is cut with a diameter of 6.75 inches. Glued to that is

a 1/4" inch piece of plywood cut slightly larger, about 7.25" in

diameter. The idea is that the larger diameter piece keeps the

drive belt from slipping off. After they are glued together, a

3/16" hole for the drive rod is drilled in the center. A two

inch hole is drilled close to the center so a locking screw can be

screwed into the center to hold the drive wheel solidly to the drive

rod. Finally a couple of brackets and a cross member are cut

that will provide a second bearing point for the drive rod.

The cross member will also keep the drive wheel from falling

off. The cross member is screwed into place, but not glued so

that it can be removed, if necessary. Note that the drive band

can't be removed without first removing the cross member.

The 7/32" hole for the bearing is drilled on a drill press with the

cross member screwed into position in order to make the hole as

close to 90 degrees to the plane of the pit as possible.

The stepper motor bracket, which is the same one that was originally

used on the barn door tracker, is attached to the pit base with

screws to allow for maintenance.

The drive band was cut using a scissors from a bicycle inner

tube. After estimating the needed length, it was glued using

contact cement and left to cure overnight. It's probably just

a bit too long, as it slips just a bit from time to time. At

some point I'll probably tweak the drive band length a bit.

The contact rubber on the drive wheel on the stepper motor was also

cut from an inner tube. As contact cement didn't seem to hold,

it was glued again with glue from a tire patch kit. I held the

rubber on the drive with a couple of small zip ties while the glue

dried. After it dried, I decided to leave the zip ties in

place.

The ties were glued to the bridge using wood glue. I used

epoxy to glue the rail to the ties rather than use spikes.

Even thought the bridge is fairly robust, it takes a lot of force to

spike track and I was afraid the act of spiking would damage the

structure.

At this point, a hole was cut in the top of the layout just larger

than the outside diameter of the pit. The dimensions aren't

critical, but I wanted to leave room for the walk. The

turntable is held in place with three bolts set in the top of the

layout and running down through matching holes drilled in the base

of the pit. It's not bolted down tight, but gravity holds the

unit in place. Nuts on the bolts can be screwed up or down to

fine tune the height of the turntable, so the turntable's rails

match the height of the rails on the rest of the layout. When

I do the scenery for the pit, I will probably lock everything down,

as going forward, I can service the turntable without removing it.

Rails were tested for length by manually rotating the turntable and

making sure that all four protruding rails are the exact same

distance from lead in tracks. I carefully ground the

ends of the long rails down with a Dremel tool to even them all

up.

Powering the Turntable

The part of this project that I enjoyed the most, was the

electronics and in some ways, this is also the easiest part for

me. I use a DCC system, but I think a lot of the principals

would be the same, no matter how you power your trains.

In order to power the locomotive on the bridge, you need to get

power to it. This must be done without running wires directly

to the track on the bridge as eventually they will get tangled, if

they are directly connected. I decided to use two parts of the

system that were already in place to get the power to the

bridge. The bridge can pick up one side of the DCC signal from

the circular track that runs around the pit and the other from the

brass drive rod. This is simple and effectively solves the

issue.

The drive rod part, was easy. I just plugged the bottom

bearing that was already in the bottom cross member and soldered one

pole of the DCC signal to that. You can see the wire running

to that in a previous picture on this page. A wire is soldered

from the top of the drive rod to one of the bridge tracks. At

this point, the connection from the drive rod to the drive bearing

seems quite reliable.

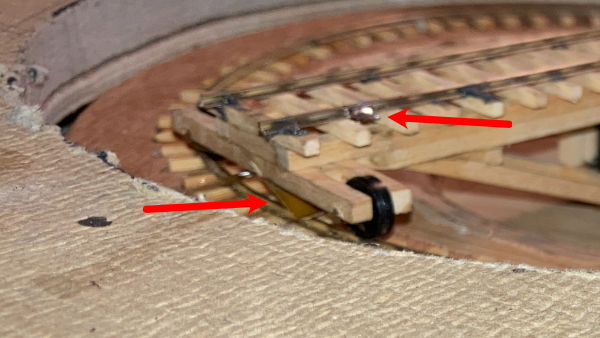

The pickup from the track was slightly more complicated. I could

have simply used metal wheel sets for pickup. The brass strips

that hold the wheels on, could have been simply connected to the

rail. Instead, I decided to attach wipers to bottom of the

trucks thinking that this may result in a more reliable

connection. I may change my mind in the future, but for now,

this is what I have done. By the time I add the walks around

the perimeter of the pit, these wipers will be almost invisible,

anyway. A hole is drilled through the bottom of the pit to

allow a feeder wire to reach the rail. This is the same

as how I connect power to the rest of the track ion the layout.

The last part of the electrical pickup problem was to prevent a

short when the locomotive moves from the bridge to the rest of the

layout. If you directly connect the bridge wiring to the

layout, only one end of the bridge rails will match polarity of the

lead in tracks. This is essentially the same problem as a

reverse loop.

The solution to this problem was to install a MRC AD520 reverse loop

module between the feeders to the turntable and the rest of the

layout's track power. Fortunately, I had one of these auto

reversers left over from my last layout. I used spade type

connectors for this connection to allow for easier maintenance.

The Stepper Motor Controller

For the barn door tracker project I had purchased a NEMA size 23

stepper motor with a 1.8 degree step angle. This motor

is way overkill for the turntable application, but it was

already interfaced to my stepper motor controller, so I decided to

use it. Since I implemented half step control, I get 400 steps

per revolution of the motor. The additional belt drive

reduction of 21:1 gives about 8400 steps for a single complete

revolution of the turntable. This is more than enough

precision for this application.

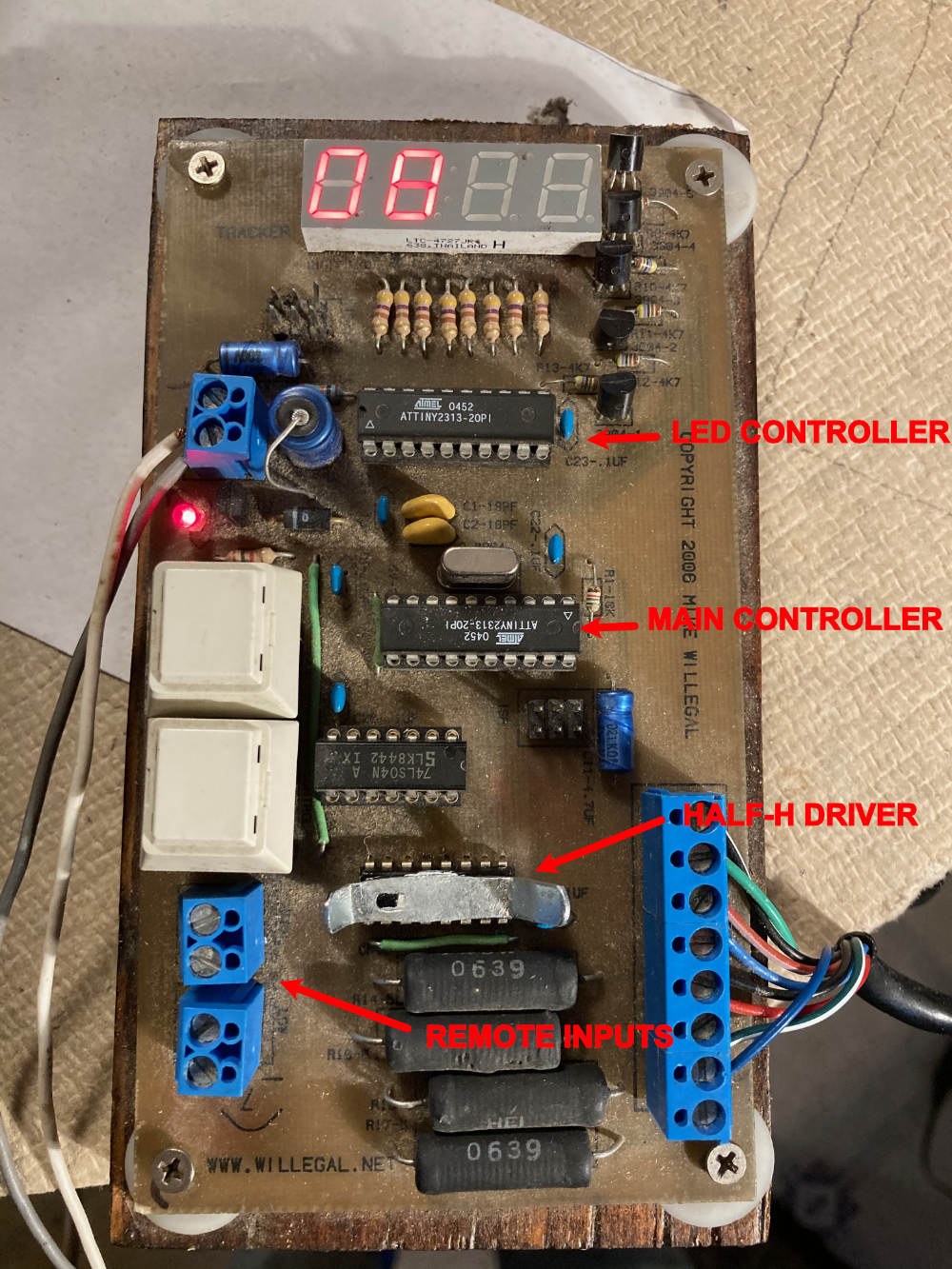

I designed the stepper controller back in 2006 for the

aforementioned barn door tracker project. I'm not going into

the details of this stepper controller design here, but I'll

highlight some of the features and firmware changes that I made for

the turntable application. If you are interested in knowing

more details, let me know.

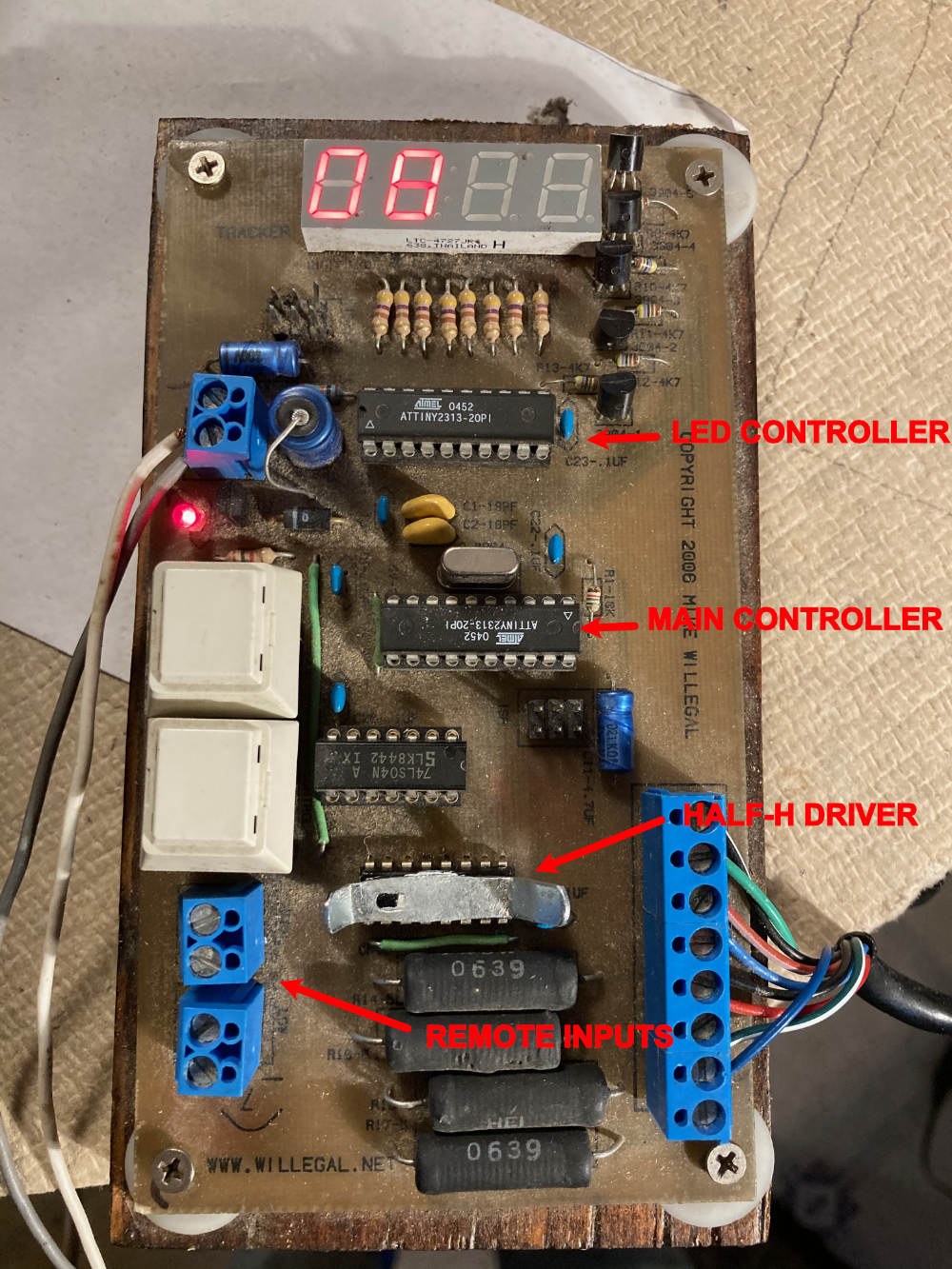

The heart of the design consists of two AVR ATTINY2313

micro-controllers and a TI SN754410 Quadruple Half-H driver

chip. It has a 4 character LED display, two on board key

switches and provisions for two remote inputs.

One of the AVRs has a very limited slave role and that is to drive

the LED display. It is connected to the main AVR through a

simple two wire serial connection, one wire for receiving commands

from the main AVR and a second wire to send responses to the main

AVR. The second response function has not been used.

This slave AVR receives commands from the main AVR which indicate

which four characters to display. The main AVR can also tell

the slave AVR to flash the displayed characters at different rates

or leave the display on, without flashing. The slave AVR has

no other capabilities.

The main AVR has the following functions.

- It sends display updates to the slave AVR whenever required

- It monitors the two on board key switches and the remote

inputs

- It maintains a 24 hour clock that holds current time in a

resolution of 1/10 millisecond

- It controls the stepper motor through outputs that connect to

the inputs of the TI Sn754410 Half-H motor driver chip.

The barn door was designed to be turned on and run for minutes at a

time as a picture of the sky was exposed on film. For the

original barn door application, the controller supported two

speeds. One was designed to allow the device to slowly track

the stars as the earth rotated. The other speed was a maximum

speed to rewind the barn door mechanism. It also

supported tweaking the speed as it tracked to adjust for the

slightly changing geometry as the barn door operated. There

was also a fine tuning calibration capability.

The requirements for a turntable application are quite

different. It only needs to run for a few minutes at a time

and needs real time operator control. The slave AVR display

driver firmware was not changed, but I ended up rewriting much

of the firmware of the main AVR.

This controller now supports 3 speeds, all of which are relatively

slow compared to the barn door rewind speed. Key switch

controls were changed to a very simple system. Pressing key

"A" causes the clockwise rotational speed of the turntable to

increase. Pressing key "B" causes the counter clockwise

rotational speed to increase. If you are moving in a clockwise

direction and want to slow down, you press the "B" key and visa

versa. Thus to rotate a locomotive that is on the turntable,

you press either key to start it moving. Then you can increase

the speed, up to two more times by typing the same key again or slow

it down or stop it by typing the other key. In practice,

operation is very simple and it is very easy to stop the turntable

so it is perfectly aligned with the lead tracks. This will

allow operators of the model railroad to mimic natural human

behavior. People will tend to slow down in order to attain

precise positioning of objects and speed up when precision is not

important.

I also added a set clock function. This is entered

automatically when the controller is powered up, or may be entered

by pressing both keys at the same time. Once in this mode,

pressing the "A" key will advance the hour and pressing the "B" key

will advance the minutes. Pressing both keys at once will exit

the clock set mode.

The old barn door application would display mode information when it

was not currently running. The display now always displays the

current time. Mode information can be deduced now by how fast

the display is flashing.

- If the controller is ready to go, but not moving the

turntable, the display does not flash.

- If the turntable is in motion, the display is set to flash

slowly

- If the set clock function is enabled, the display will flash

at a fast rate.

The remote inputs were originally designed to monitor limit switches

so the controller could stop the barn door when it reached either

end of it's allowed travel. The new firmware monitors these

inputs exactly the same as the on board key switches. One

remote input takes on the role of key "A" and the other key

"B". With this capability, I'll be able to add a secondary

turn table control panel to my layout. The plan is to add the

second control panel on the other side of this module, next to where

all the track switch controls are located.

Finally, since the slave display controller AVR never sends anything

back to the main AVR, I should be able to build one or more

additional slave clock displays by tapping into the signal going

from the main AVR to the display AVR and propagate it across my

layout.

Power consumption when not actually spinning the turntable is about

60 milliamps. When actively turning consumption goes up to

about 350 milliamps.

The Finished Turntable

If you have questions or comments, feel free to contact me at (mike@willegal.net)

Back to

Mike's Hobby Home Page