Construction Hints

Making Blasted Rock Faces

I recently redid the rock face below the Amtrak F7 in this picture. The

original face just didn't have the feel of a rock face. I tried painting

it several times and just couldn't come up with the look I wanted. Finally

I bit the bullet and got out the plaster. Since I had painted the old surface

the night before, I didn't bother to dampen it which I normally would have

done. I mixed 2 cups of plaster with 1 of water. Then I tried to plaster

over the face, but the stuff was too soupy. I then added a bit more plaster

to the mix and waited a couple of minutes for it to start to thicken. Once

it started to thicken, I used a putty knife to apply the plaster along the

rock face. When I had a good thick covering across the whole face, I used

the same putty knife to to sculpt the face so that there were few rounded

surfaces. I wasn't trying to model rock as much as trying to create a face

with lots of edges and few smooth rounded corners. I also used the edge of

the putty knife to create those rounded grooves you always see in blasted

rock faces. I would assume that these are the holes drilled to hold the blasting

charges used to clear the rock. You can't see this detail in this picture,

but if you look at real blasted rock faces, you will know what to do. I

guess one could use rock castings to make this face, but for me, it just

seemed like too much trouble.

Painting this face involves several steps. First use a light gray to

provide the base color. Paint the whole rock face with this light gray.

I use the cheap craft paints you can get at Walmart or any store that carries

craft supplies. There is no point in using fine modeling paints on scenery.

Next step is to put in highlights of brown, green, yellow and maroon. I

used craft paints for this, as well. For these highlights, I will dilute

the colors a bit in water so they don't go on too heavy. Just dab the color

on a bit here or there. Also as you switch colors, reuse the same cup that

had the previous color in it and mix some of that old color into the new color

and onto the brush. Don't worry about being perfect. If you don't like

the look you end up with, just start over again with the light gray base.

Finally, I put a wash of india ink heavily diluted in isopropyl alcohol.

By now I've added some more paint and ground foam to this rock face and

this is now what it looks like. In addition, the layout has had a quite a

bit more wear and tear since the original photos.

Nailing track nails into plywood

We used 3/4" plywood sub roadbed and cork roadbed on our railroad. The

Atlas track nails we use don't go into the plywood very well, usually bending

instead of going in straight when driven by a tack hammer. The solution

I am currently trying is to put a track nail into a pin vise and using the

nail to drill a pilot hole. I originally tried a cordless drill/driver,

but the chuck wouldn't hold the track nail. This seems to working OK, so

far. Got the idea from my dad when he said some finish carpenters use the

same trick to drill pilot holes in trim, to avoid splitting.

Fences for tunnels

My dad and I came up with what I think is a pretty good system for making

and installing guard fences in tunnels. Simply rip a long length of wood

about an inch and a half wider than your sub roadbed (say 3 1/2" for 2" wide

sub roadbed). Then rip a 1/8" dato 3/8" deep about 1/4" or so in from each

side. This will be a groove that should tightly hold strips of 1/8" hardboard

that will be the fence itself. Crosscut the wood into 2" wide pieces to

make bracket s. Screw the brackets every foot or so to the underside of your

sub roadbed with the groves for the fences facing upward. Now cut appropriate

strips of that 1/8" hardboard and they can be simply placed into the grooves

into the brackets. They can be removed at any time for access to the track.

Model fences

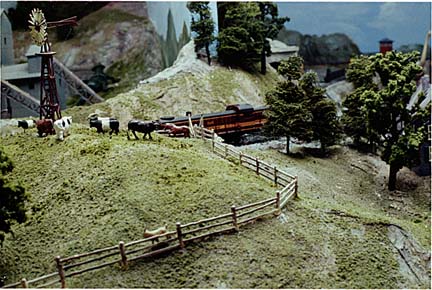

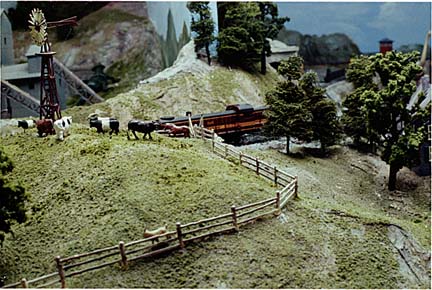

I built this fence on our layout using Atlas rustic fence as a starting

point. Since the pasture was not totally level I had to cut and splice the

pieces from several kits together to keep the posts vertical. All real fences

are built with the posts vertical. I also used those thin grocery store

spits in order to extend the posts in some places, since they are almost

the same diameter as the Atlas rustic fence posts. I didn't use the bases

provided with the rustic fence after the first few sections were in place.

I simply drilled a small pilot hole in the plaster and glued with fences

to the plaster with white glue.

Actual fences may be built with or without the rails running horizontally.

I made mine horizontal simply because it was easier to do.

Note the Lakenfelder (Dutch Belted) cattle in the picture above. We saw

them on a trip recently and thought they were very unique, so we incorporated

them into our layout.