After several years of being broken, I finally took the time to repair the remote starter on my 2004 Malibu.

Based on internet searches, I had a pretty good idea that the problem was in the switch that detects whether the hood is open or closed. This switch is designed to protect anyone that is working under the hood from harm due to a remote start event.

The first step of this job is to remove the hood latch, since the switch is integrated in with it. This wasn’t too difficult, but disconnecting the remote release cable was tricky and the connector for the switch harness was underneath a plastic bezel that couldn’t be removed. However one side of the bezel was bolted down. I unbolted it and pried the bezel up so I could get at the connector, which was underneath.

I now had the latch out and examined the integrated switch, which was riveted on. Testing the the three leads coming off switch with an ohm meter revealed no connection, no matter what position the switch was in. I wondered if it could be fixed, so I decided to drill out the rivet and remove it from the latch assembly. Then I cut off the plastic rivets that held the sides of the case together to get a look inside.

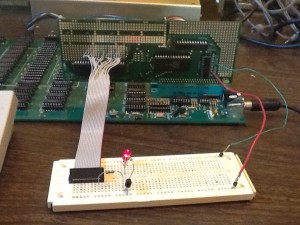

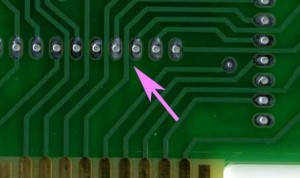

The mechanism was rather interesting, it held two sealed magnetic switches mounted on small PC board. One of the two switches was activated at any time by a magnet that moved with the latch mechanism. The sealed switches were defniately designed for the hostile environment at the front of my car. However, the weakness of the design was that traces on the PCB were exposed to whatever could get into the switches. They had corroded to the point of failure.

Well I got out my soldering iron and soldered some wire where the traces were supposed to go. Then I attached the switch to the cars electrical system and sure enough, the remote starter came to life for the first time in a number of years.

With the fix proven, I used crazy glue to put the switch case back together and attached the switch back to the latch with a small screw and nut, dropping a bit a glue on the exposed threads so it wouldn’t work loose in the future. I then reassembled everything and successfully verified the fix.

Now what about the title. I have several complaints about this design in terms of servicability.

Though removing the latch was not that difficult, it was made more difficult by the limited space available to access the three bolts holding the latch to the car. Getting under the plastic bezel to access the electrical connector was also a pain. Riveting this switch to the latch ensures that normal people will have to replace the latch with the switch, increasing cost of repairs by quite a bit.

All in all this isn’t too terrible a repair job. It just took longer than it should have, because the overall design wasn’t optimized for serviceability.