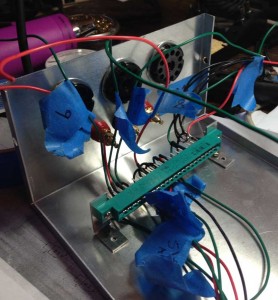

Here is a picture of my first reproduction SCELBI I/O cable. I’ll need to build four of these before I can hook up the reproduction TTY and Cassette interface chassis that I plan on building.

SCELBI I/O Cable

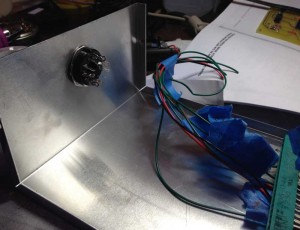

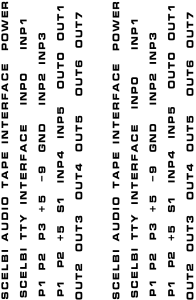

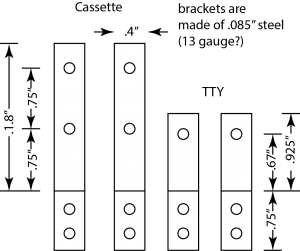

For connections between the main and I/O chassis, SCELBI used a standard cable that featured 11 pin Amphenol connectors on each end. Male connectors on one end connected to the main chassis and female connectors connected to the I/O chassis. The connections are straight through, pin 1 to pin 1, pin 2 to pin 2, etc. They used 12 conductor cable with two wires connected to pin 11 (ground) on each end. The cables that I’ve been able to examine, averaged approximately 32″ long from connector face to connector face. The power supply cables and the cables that ran from the peripheral chassis to the peripherals themselves were different than these cables. Several different kinds of SCELBI cables can be seen on the CHM website.

12 conductor cable can be expensive. I ended up finding a roll of 50′ of Belden type 8747, which should be enough for my purposes. It cost me, $50, including shipping. The reel that the cable came on, has a UL stamp dated Nov 1, 1979. It’s been around almost as long as the original SCELBIs!

Original SCELBI cables had metal shrouds with strain relief covering the interface between the cable and the connector at each end. A while back, I bought a lot with two varieties of plastic shrouds on eBay. I’m using a different style of the plastic variety on each end of my reproduction cables. I’d use the smaller shroud on both ends, but I don’t have enough of those for all the cables that I need to build. At some point, I hope I’ll find a batch of the original metal type shrouds and be able to do a swap.

The Amphenol connectors and shrouds are expensive, but you can sometimes find deals on eBay or in surplus dealers inventory. If you just look at standard suppliers like Mouser or the like, connectors may cost up to $14, each, and the shrouds about half that. If you don’t shop around, you may end up paying close to $50 for the parts to build a single cable. I probably have a bit less than half of that invested in the pictured cable.

I once ran across an ad in a 70’s era magazine that listed the connectors for $.25 each. Those days are long gone.