I figured I would report on my SCELBI exhibit operations at VCF SE 1.0. I will also cross post this to the new yahoo group, retro-restore.

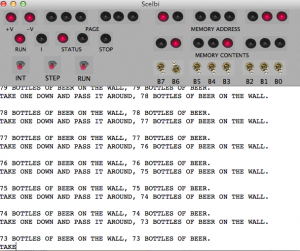

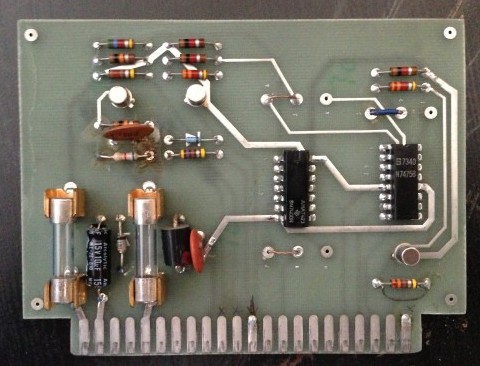

Saturday was dedicated to running the SCELBI calculator program. Toggling in the bootloader before exhibit opening, went without major issues, though I found that focus on toggling was a little hard to keep with numerous other people around getting the facility ready and getting their exhibits ready. No significant problems with downloading and pretty soon I had the program running.

I had left the divide by zero error handler to just halt the CPU. This turned out to be a good way to demonstrate front panel operations, as I just needed to divide by zero in order to halt the cpu. I would then need to toggle in a jump instruction in order to get the program running again. I did have a few issues during the day when the program appeared to stop accepting input. I think the main reason for this, is that the parser is rather particular, expecting only certain characters during input at any given time. Other characters are ignored, making it seem like the program or machine is stuck, when, in fact, the operator is typing the wrong thing. Anyway, the program ran all day, without any need to reload it, until I took it down to demonstrate during my talk.

The second day, I was planning on demonstrating Mark Arnold’s 1K Mandelbrot program. I arrived just 20 minutes before exhibit opening and because I was also demonstrating a Mimeo and had to set that up, and didn’t have time to toggle in the bootloader before opening. I had to do it, while showing off my exhibit. The Mandlebrot program needs to use location zero, so I had to relocate the bootloader. Last time, I did this, I had no issues, but this time my math skills failed me and I spent a considerable amount of time trying to make the Mandlebrot program load right on top of the bootloader. Finally after realizing the error of my ways, I retoggled the bootloader into a better spot and got the Mandlebrot program loaded and running.

If I had been thinking straight, I could have loaded the bootloader into the new location, with the bootloader that was loaded in the wrong place. The SCELBIgenerated Mandlebrot images for the rest of the day, without error.

The bottom line is that the SCELBI ran all weekend, the clock remained stable enough to support RS232 bit-banged I/O without error. The power supply worked great.

A lot of people that had never heard of it, were exposed to the SCELBI for the first time. And finally, I overheard one person say that the reproduction SCELBI was the coolest thing at the show.

Things I would change. I would probably run the Mandlebrot on Saturday, when things were busiest. I also need to find a teletype or current loop terminal,because some people were confused by the Powerbook running a terminal program acting as the terminal.

It was wonderful meeting everyone who came to the show and if you didn’t come I recommend you make an effort to attend a VCF, if you get a chance.