See my earlier post describing my interview with Howard Cantin.

I sent the excerpts of this interview to Woz to get his impressions. Woz was happy to see the interview and responded with some interesting comments. My email is indented and in gray, Woz’s response is not. This is published in my blog with Woz’s permission.

On Apr 17, 2012, at 9:27 AM, mwillega wrote:

Hi Steve,

A couple of weeks ago I had a telephone conversation with Howard Cantin. Howard is known as the PCB layout person on the Apple 1. Apparently he was also involved in the first Apple 2 layout. A few of the things he said, are quite different than what I have heard and read elsewhere. I’d be interested to know what you thought of what Howard told me.

My comments below.

THANK YOU THANK YOU THANK YOU. It’s rare to find the true stories from back then.

What follows are taken from notes taken during the call with Howard. The call was not recorded, so words are mine.

Background

Howard worked from his house for clients including Atari and Apple. Howard says he laid out all the boards for the first four years at Atari, until Nolan Bushnel sold the business. He also laid out first boards of other electronics startups in valley that became major players. Though he couldn’t remember the names of others, he says he did the first PCB for Intel. Howard says he was well connected to insiders in the valley electronics community and was the person to go to, when a PCB layout was needed. Howard related how he set many of the standards in PCB layout that were followed by others.

Nolan Bushnell of Atari was often in a hurry and pushed Howard to hurry along a design. Howard says he was a fast designer, partly because of working under the pressure provided by Nolan. He could add a chip to a layout in hour.

Steve Wozniak

Regarding Steve Wozinak, Howard related to me, the often retold story about how Woz created a game design that used 60 parts instead of the 100 in the design that preceded it. Howard related that engineers at Atari couldn’t understand the design. Because they couldn’t understand it, Atari ended up not using it.

How Howard Worked

Most designs had an edge connector, so he would start with that and then add parts that connected to the edge connector. Then he would connect those parts to the parts that connected to those parts and so on. Vias were expensive and to be avoided, and would take up the space need for 3 traces. Howard provided his original artwork and photographic transparencies ready for the PCB manufacturer to his clients. Howard often didn’t negotiate price before taking on a job, but a typical cost was 6 to 8 dollars per chip. Howard worked directly from customers schematics, and is still proud of his ability to produce a result that matched the schematic perfectly.

The Hobby Computer

The first board that Howard did for Jobs and Wozniak was a computer to be sold to the hobbyists at the local computer club. Howard says that this computer was the board that provided the financing to start Apple Computer. Howard refers to this as a hobby computer, not an Apple Computer. Howard says the two Steve’s always were together and they conducted their discussions with him together. To pay for this computer, the Steve’s tried to trade an old Fiat Station Wagon for services rendered. Howard asked for cash, so the Fiat was sold and proceeds used to pay Howard. As some point, stock was offered, but this was also refused.

The First Apple Computer

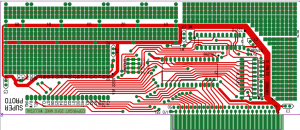

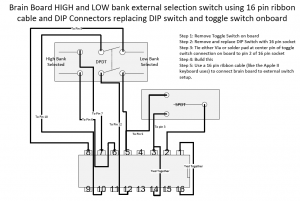

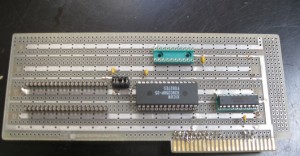

Steve Jobs appeared to be a perfectionist to Howard. During the layout of the first Apple Computer, Howard had three proposed layouts with different form factors. There apparently was a lot of back and forth figuring out the form factor. Finally, Howard suggested one of the layouts happened to exactly match the size of a piece of legal paper (8.5×14) and Jobs selected that one. The proto area in the corner of this computer was empty and it was Howard’s idea to put pads for a chip and an array of pads that became the proto area.

Though Howard did the main chip placement on this second layout, Howard paid a woman to lay the tape for traces. She was not very good and the traces she laid were not very straight. Jobs wasn’t satisfied and took the design and had it redone digitally. Jobs later told Howard that this re-layout cost Apple three months. Howard asked Steve why he needed to redo the layout and Steve said he was only going to do it once in his life.

Howard did not use that woman for laying traces again. Howard told me that after that project, that he would have refused more work from Apple. In any case, Apple didn’t come back to him.

PIRACY

Howard also mentioned that he thought that the one of the Steve’s took a picture of an Atari board that he happened to be working on as the same time he was working for them. He thought that the Steve’s might have used this picture to duplicate an Atari design in some way. Howard did not have any specific details about what exactly was done with the image. Howard also said he talked on the phone with someone in England that might have been investigating another pirated Atari design. At one point, Nolan Bushnel asked Howard to pirate another design, but Howard refused. Howard now thinks that this was Nolan’s way of checking Howard’s honesty.

Anyway I have these comments about what Howard said. I’d be interested in what feedback you had.

He is confused about the “Hobby” computer that was the Apple 1 and the “first Apple Computer” that was the Apple II.

When we met Howard at his home in Scotts Valley (I believe that’s where) we had not yet come up with the name Apple.

Howard’s story says the vehicle sold to finance the Apple 1 was a Fiat Station Wagon, not a Volkswagon bus.

It could be. It was some vehicle that really wasn’t being used as I recall. All I know is that I sold my most valuable possession, my HP-65 calculator, to come up with my half. Steve and I always did everything in business 50/50 (with regard to money).

Do you remember taking the Apple II layout that was done by Howard’s subcontractor and then reworking it in a digital format?

This does match my recollection, although the steps and reasoning for the switch to computer layout I wasn’t close enough to. I saw it being done but I don’t recall a negative reasoning, just that computer layout was ‘better’.

Finally, his story of Steve Jobs and you somehow stealing an image of a Atari PCB and making some kind of profit from it. He was very vague about exactly what was done. That part of Howard’s story seems incredibly unlikely to me, especially given the inconsistantcies with the rest of the story.

I would never do such a thing. I never photographed any Atari board nor remember it being done while I was around, but it’s possible that Steve Jobs did photograph one at some other time. I’m against stealing designs. Look at my designs, for example. You won’t find a bit of them extracted from some other design or data sheet. Check out almost every other hobby computer design around then and that’s all they were, duplicates of Intel data sheets. My design was always so original that it’s partly why Atari couldn’t understand it (Breakout).

This story rings incredibly true and accurate, which is unusual in our business. Obviously it’s first hand from Howard and not filtered through communications types in companies or the media.

Thank you for letting me know I’m not going crazy with all the things others have reported on these matters.

— Woz

Thanks and best regards,

Mike W.

Continue reading →