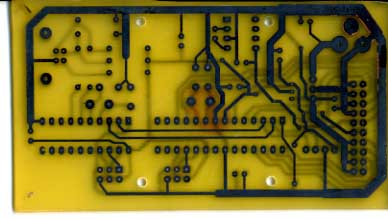

I have all the parts and etched the board this morning. Registration between layers isn’t as good as I’d like, but it will do for a prototype. It will take another evening to drill holes and solder in the components. Some of you may wonder why I go through the effort of making a PCB for a prototype. Well I think a PCB results in a vastly more presentable finished board and I like the esthetics of it. The result should also be a little more reliable than the results of other prototype processes. I don’t think that it is that much more trouble than say wirewrap or point to point prototyping. Finally, creating a prototype using the same artwork that a production house would use, makes going for a production run much less risky.

The board is designed to fit an a Serpac A20 enclosure, as used on my shutter tester project – http://www.willegal.net/light/tester.JPG. This is not the cheapest enclosure, but I think it is a pretty good looking off the shelf box. I’ll have to come up with some kind of cool decal to put on top of it.

-Mike W.

PS In this image I haven’t yet removed the ink from the laser printer image that is used to form the resist.