Mike's Super D'Lux, Apple ][ Forever, Home Brew,

Focal Plane, Shutter Tester

I retain copyrights to this site and this design, so anyone attempting

to reproduce this design for other than personal purposes, should

contact me first.

See my Optical Timer/Counter

page for my latest micro-controller based shutter tester design.

After far too many hours of experimentation (just ask my family), I think

I've come up with a quality shutter tester design. You should be

able to build your own Super D'Lux Home Brew Shutter tester for under 100

dollars. Keep in mind that complete Apple ][ systems can easily be

found for less than $50 on ebay and less, elsewhere. Presented here

is the fundamental design information and the software required. As

time becomes available, I'll be adding more details.

The light detector design is based on a fairly sophisticated cascode circuit

feeding a comparator. A couple of other designs were tried and abandoned

to due slow signal transitions. Using current limiting resistors

or even a current source, resulted in a rise/fall times of several hundred

micro seconds. Several hundred micro seconds rise time creates real

problems in accuracy at high shutter speeds, since 1/1000 is an exposure

of only 1000 micro seconds.

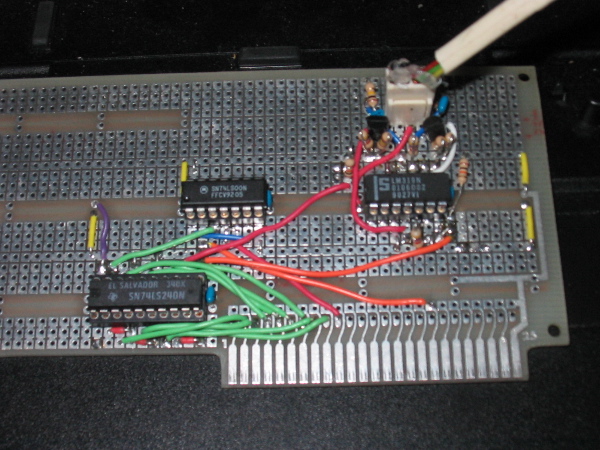

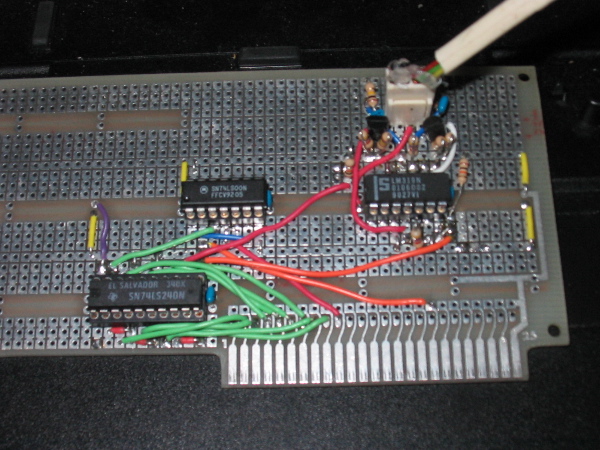

The prototype Super D'Lux was built on a proto board and plugs into a

slot on an antique, but working Apple II computer. Apple ][ specific

proto boards are hard to come by, but I understand proto boards designed

for IBM XT's can be cut down and adapted for Apple ][s. The

bus interface is very simple and could easily be adapted to other micro

computers. In fact the Apple ][ comes with a couple of TTL inputs

in the game port that could be used without any additional interface circuitry.

However you still need to find a place to hold the rest of circuitry

and the software will have to be adjusted to match your design. In the end,

I decided to build the first Super D'Lux on a proto board.

The first prototype was built on a proto board that I recently bought

on Ebay for about $8.

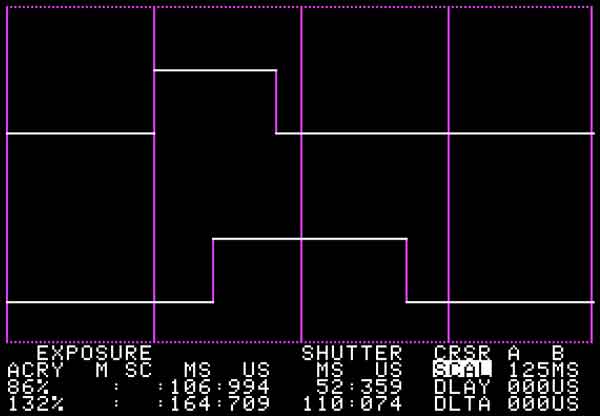

Super D'Lux software directly samples the detector, times the shutters

and displays the results in text and graphical formats. It even

will estimate shutter accuracy for you, automagically. Maximum measured

exposure is about 4 minutes. Minimum is under 1/1000 second. Maximum

shutter travel time between the two sensors is about 1 second. If

you choose to utilize another kind of computer you will have to port

the software and adjust the timing.

Detector

My detector is a block of wood with the two photo transistors mounted

inside exactly 18mm apart. In front of the detectors is a piece

of styrene plastic with two slits in front of the photo transistors. The

slits were created by heating up a chisel shaped exacto blade and

running it through the plastic. The plastic is painted black to

minimize reflections within the detector. On the surface this component

looks very simple. However you must be as precise as possible when

creating this unit. The accuracy of the shutter tester is more dependent

upon this component than all others combined.

You should use a variable light source in conjunction with the shutter

tester. A home made meter tester, with variable brightness capability,

can be seen on my tools page. Adjust the light to the minimum level

that still registers exposures at medium and fast shutter speeds.

Using more light than necessary will probably result in exposure readings

that are higher than actual, because ot scattered and reflected light switching

on the photo transistors too soon and a delay in turn off.

Design and construction of the photo detector is critical for accuracy

at high speeds. If you are having trouble adjusting the high speeds

on your camera, when using your home made shutter tester, it could be that

your detector needs work. See the bottom of this page for more information

pertaining to the accuracy any shutter tester.

Hardware Circuit

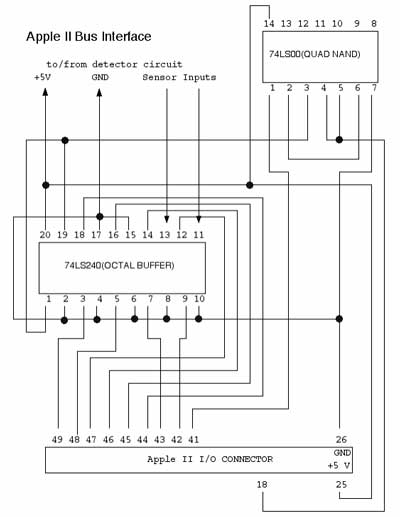

Here is the hardware schematics for the Apple ][ bus interface. One

reason why I choose the Apple ][ was that interfacing to this bus is trivial.

For instance, adding latched outputs to this interface only requires

one more chip, should you need them. If you choose to use a different

processor, such as a PIC or Commodore 64, you will have to replace this

circuit with an appropriate design for your processor. As mentioned,

the game port on an Apple ][ has 2 ttl inputs that could be used instead,

but you will still have to find a place to mount the rest of the circuit

and the software will have to be adjusted accordingly.

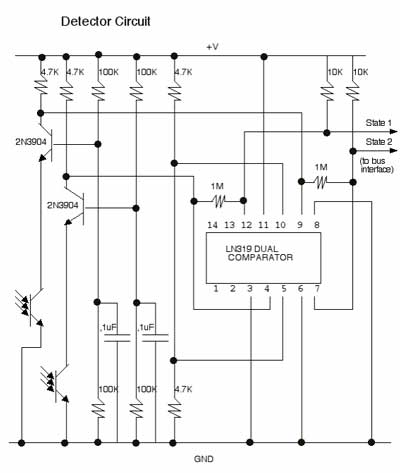

Here is the schematic for the detector circuit. I believe inclusion

of the LM319 comparator is most likely overkill, but I have included it

because I was using it prior to the change to the cascode design. It

can probably be omitted completely or replaced with another comparator.

The 2N3904 can be replaced with a 2N2222 transistor, with little or

no measurable difference in performance. This transistor design is

called a cascode type circuit. The response time is a few micro seconds

for this detector, instead of several hundred for other designs that I tried.

One enhancement you may consider, is adding a variable resistor

in place of one of the 100K resistors in order to calibrate both sensors

to equal sensitivity. I have not found this necessary on my prototype.

Software

One reason for using the Apple II was simple programming model and the

existence of simulators that allowed software development on a Macintosh

running OS/X. I developed the software completely in a simulated environment

on my Macintosh using a program called Virtual ][. The assembly code

was developed using a free 6502 assembler called ACME. Apple ][ simulators

and 6502 assemblers exist for other platforms. You should be able

to download and run my shutter software on most any simulator you find.

You can use the simulators method for simulating the game push buttons,

to simulate shutters opening and closing of shutters, if you assemble the

machine code with the !set simulator flag turned on. This program

is hard coded to assume the board is mounted in slot 4. You can change

the "sensor = $c0c0 ;card

plugged in slot 4" line and reassemble to move the card elsewhere. I

don't feel it would be worth the effort to auto detect the slot and adjust

automatically.

Loading the software into an Apple ][ is quite simple if you have a

serial card in your Apple. There is much data elsewhere on the web

on how to move programs onto an Apple ][. However, one thing you

must be aware of is that you must POKE 17408,0: POKE 104,68 and type "NEW"

prior to downloading the basic program into the system or the program

will not run correctly after it is downloaded. Once the basic program

is loaded into your Apple ][, save it to disk with the "SAVE SHUTTER" command.

The assembly code is loaded at $4000 and has a length of $400. Once

loaded into the system save it to floppy disk by typing "BSAVE ROM,A$4000,L$400.

The basic program will load it automatically when it starts running.

One last thing. Proper timing is dependent upon a careful

analysis of CPU cycles used by each instruction in the assembly source.

It is based on use of a Apple ][ running a standard 6502 at 1.023

MHZ. If you are running a different clock speed or processor variation,

the reported timing may be off. Timing on the simulated version

will also be off, because of the different method used to sample the game

input switches. This can be corrected through careful analysis of

the actual processor clock speed and clock cycles used by each instruction.

The adjustments are taken care of in lines 1111 through

1129 and on line 10020 of the basic program. As designed, the software

will sample the inputs every 16 micro seconds, which is around 64,000 samples

per second. This provides 64 samples for 1/1000 exposure, providing

accuracy of better than 5%. At higher shutter speeds, accuracy will

suffer accordingly.

Basic

source code is found here.

Assembly

source code is found here.

Machine

code - not for simulator

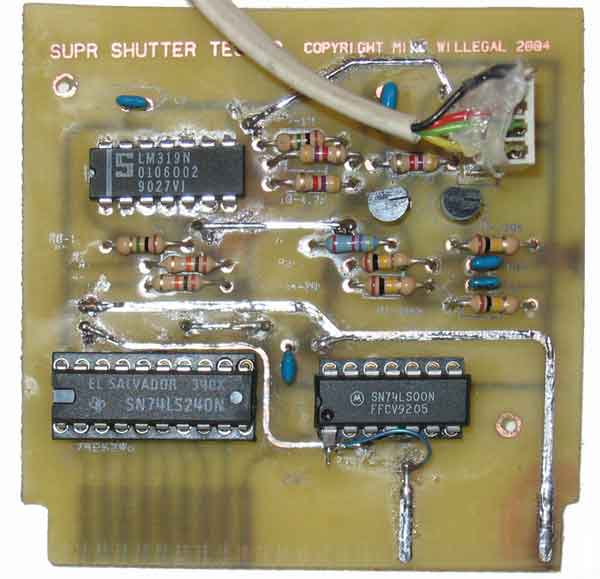

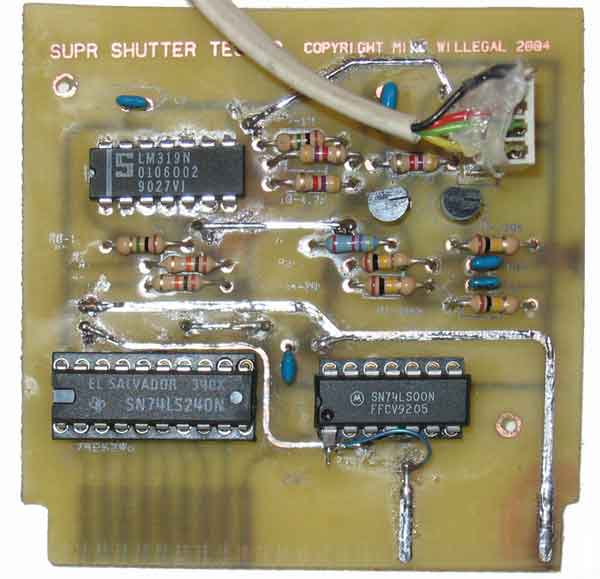

The Supr Shutter Tester on a Real PC Board!

I was so proud of my design that I had to replicate it on a custom

PCB. I have never gone to the effort of making a PCB, on any previous

project, and this was a fun learning experience. It is made using

the laser printer/photo paper/iron technique described on a number of web

sites. Apple expansion cards require a double sided design with a card

edge connector, which seriously complicates construction. I drilled

the holes all by hand with a pin vice using either a #60 or #70 (vias and

transistors) bit. The result is not real pretty, and the layout

has one mistake that I had to correct by cutting a trace, lifting a pin

and running a jumper wire, but it works. Corrected artwork is available

in postscript format upon request.

Accuracy Issues

The performance of an electronic shutter tester is dependent upon

a number of factors. Let's consider some of these factors, using an

real world example at a shutter speed of 1/1000.

- Velocity of Shutter. This can be calculated by dividing curtain

travel time by distance. The horizontal travel curtain in Minolta

SRT 101 should be adjusted to cross the 36mm focal plane in 13.5 to 14 milliseconds.

Lets assume 14 milliseconds and divide by the distance of 36mm. The

result is 14milliseconds/36mm = .38889 milliseconds per millimeter.

- The time between the opening of and the closing of the shutter.

This should be equivalent to the shutter speed, in our example is 1/1000th

of a second or 1 millisecond.

- Combining the velocity with the exposure will result in the distance

between the opening and closing shutter curtains which in our case is 1millisecond/.38889milliseconds/mm

= 2.57mm.

- Now consider the size of the photo transistors or other electronic

sensors that is needed to switch the circuit on and off. Assume

the detector is 1mm across. For a 1/1000 or 1 millisecond exposure,

the detectors relationship to the opening between the opening and closing

shutter is 1mm/2.57mm or 37 percent. It should be clear that

a smaller sensor is better than a larger sensor.

- Phototransistors have a lag time between being switch on and or off

and visa versa . Each particular phototransistor design is different

in this regard, but it is easy to find off the shelf photo-transistors

that have a lag time of 10 micro seconds or less. This response

time is similar in both turn on and turn off functions, so basically cancels

itself out. This fast response time and the fact that it is pretty

much symmetrical for turn off and on should result in only small error.

- Phototransistors and other photoelectric devices in a real

world circuit don't instantaneously turn on or off the moment a single

ray of light touches the sensor. Phototransistors have a curve that

allows more current to flow as more light reaches the sensor, at least until

it is saturated. As the opening curtain travels across the focal

plane, it allows more and more of the light to reach the sensor, which in

turn, allows more current to flow, until enough light reaches the sensor

to saturate it. The circuit in which the phototransistor is placed

will switch on after a predetermined amount of current flows. Bottom

line is that the circuit turns on sometime after light begins hitting the

phototransistor, not immediately. The circuit turn on point depends

on both light intensity and the circuit in which the photo transistor is

placed.

- There is a similar lag time for turn off of the circuit. A

properly designed circuit will turn off in a inverse function compared to

the turn on. If this is the case, the lag for turn on and turn off

will mostly cancel each other out.

An analysis of these factors reveals that to minimize error, one item is

the most critical, assuming that the sensor designed is as small as practical.

- Symmetrical electronic turn-off/turn-on performance.

In other words, it is most important that the function that turns on the

sensor output is as close as possible to the function that turns it off.

Back to Mike's Hobby Home Page